Buehler SimpliMet 4000 Hot Mounting Machine

Buehler SimpliMet 4000 Compression Hot Mounting Machine – High‑Speed Automatic Mounting Press

The SimpliMet® 4000 is Buehler’s high‑speed compression hot mounting machine for 1–1.5 in and 25–50 mm specimens, built to remove bottlenecks in metallography and quality‑control labs. It uses automatic electrohydraulic operation, a wide 1000–4400 psi pressure range, duplex mounting for two mounts per cycle, and a compact 12.25 in‑wide footprint to deliver fast, consistent mounts with excellent edge retention across steels, alloys, welds and coatings.

SmartCool™ intelligent cooling automatically stops cooling at about 40 °C, while a dedicated thermoplastic mode optimizes cycles for transparent media such as TransOptic™, and the 350 psi PreLoad function protects delicate or heat‑sensitive specimens. Together with simple front‑panel controls and low‑effort “weightless” closure, the SimpliMet 4000 hot mounting press gives 24/7 production labs a reliable, space‑efficient way to increase mounting throughput and maintain reproducible compression mounts using Buehler mounting compounds and accessories.

Technical Specification of Buehler SimpliMet 4000

| Press Operation | Automatic electrohydraulic hot compression mounting press for metallographic specimens. |

| Mount Sizes (Inch) | 1 in, 1.25 in, 1.5 in molds. |

| Mount Sizes (Metric) | 25 mm, 30 mm, 40 mm, 50 mm molds. |

| Pressure Range | 1000 – 4400 psi [70 – 300 bar], adjustable in 50 psi [5 bar] increments. |

| PreLoad Function | 350 psi [24 bar] gradual preload to protect delicate or heat‑sensitive specimens. |

| Heat Time | User‑selectable 1 – 20 minutes, adjustable in 10 second steps. |

| Heating Temperature | 120 – 430 °F [50 – 220 °C] operating range. |

| Heating Power | 1500 W @ 115 VAC / 1900 W @ 230 VAC. |

| Cooling Time | User‑selectable 1 – 30 minutes or SmartCool™ automatic cooling to approximately 40 °C. |

| Thermoplastic Mode | Dedicated mode for TransOptic™ and other thermoplastics with controlled linear cooling. |

| Noise Level | Max 62 dB at 1 m while raising/lowering ram with mold open. |

| Intended Use | Single‑station compression hot mounting machine for 24/7 metallography and QC labs. |

| Electrical Supply | 85 – 264 VAC, 50/60 Hz, single phase. |

| Working Temperature | 41 – 104 °F [5 – 40 °C]. |

| Working Humidity | 30 – 90 % relative humidity, non‑condensing. |

| Water Inlet | 1/4 in OD or 3/8 in OD tubing connection. |

| Water Outlet |

Drain: 1/4 in ID x 1/3 in OD hose. Vent: 1/4 in ID x 1/2 in OD hose. |

| Length (Overall) | 26.00 in [660 mm]. |

| Length (Rear to Front Feet) | 21.25 in [540 mm]. |

| Width | 12.25 in [311 mm]. |

| Height (Closed / Open) | 19.62 in / 20.62 in [498 / 524 mm]. |

| Weight | 120 lb [54 kg]. |

| Compliance | CE, PSE, RoHS, WEEE. |

Key Features & Benefits of Buehler SimpliMet 4000

- ✓ High-Speed Compression Mounting: Automatic electrohydraulic hot mounting press designed for 1–1.5 in and 25–50 mm specimens, ideal for high-throughput metallography labs.

- ✓ Duplex Mounting Spacer: Included duplex function allows two mounts to be produced in a single cycle with minimal impact on total cycle time.

- ✓ SmartCool™ Intelligent Cooling: Monitors mount temperature and automatically stops cooling around 40 °C, reducing wait times and preventing overheated ejection.

- ✓ Thermoplastic Mode: Dedicated mode optimized for transparent thermoplastic media such as TransOptic™, with controlled linear cooling for clear, void-free mounts.

- ✓ Wide Pressure & Temperature Range: 1000–4400 psi (70–300 bar) pressure and 120–430 °F (50–220 °C) temperature range to support a broad range of Buehler mounting compounds.

- ✓ PreLoad Function: 350 psi (24 bar) gradual preload to protect fragile or heat-sensitive specimens before full pressure is applied.

- ✓ High-Efficiency Mold Design: Low thermal mass mold assembly and powerful 1500/1900 W heaters deliver fast heat-up and cool-down cycles.

- ✓ Compact Footprint: Only about 12.25 in (311 mm) wide, allowing multiple SimpliMet 4000 units to fit on the same bench for maximum throughput.

- ★ Maximum Throughput: Duplex mounting and SmartCool reduce overall cycle time, helping labs eliminate mounting bottlenecks and increase sample output per shift.

- ★ Consistent Mount Quality: Precise control of pressure, temperature, heat and cool times delivers reproducible compression mounts across operators and shifts.

- ★ Improved Sample Protection: PreLoad and thermoplastic modes minimize mechanical and thermal stress, protecting delicate microstructures and surface features.

- ★ Flexible Application Range: Supports Buehler PhenoCure, EpoMet, KonductoMet, ProbeMet and TransOptic™ to cover routine QA, conductive mounting and transparent analysis mounts.

- ★ Optimized for 24/7 Use: Rugged design, compact size and simple controls make the SimpliMet 4000 suitable for continuous production environments.

- ★ Easy, Ergonomic Operation: Intuitive interface and low-effort “weightless” closure reduce operator fatigue and training time.

- ★ Space-Saving Bench Layout: Narrow width and integrated hydraulic system free up space for grinders, polishers and other Buehler preparation equipment.

Ordering Information

| SimpliMet® 4000 | |

|---|---|

| Part Number | Voltage |

| 20-1011-5001 with 1 in Mold | 85–264 VAC, 50/60 Hz |

| 20-1011-5025 with 25 mm Mold | 85–264 VAC, 50/60 Hz |

| 20-1011-5125 with 1.25 in Mold | 85–264 VAC, 50/60 Hz |

| 20-1011-5030 with 30 mm Mold | 85–264 VAC, 50/60 Hz |

| 20-1011-5150 with 1.5 in Mold | 85–264 VAC, 50/60 Hz |

| 20-1011-5040 with 40 mm Mold | 85–264 VAC, 50/60 Hz |

| 20-1011-5050 with 50 mm Mold | 85–264 VAC, 50/60 Hz |

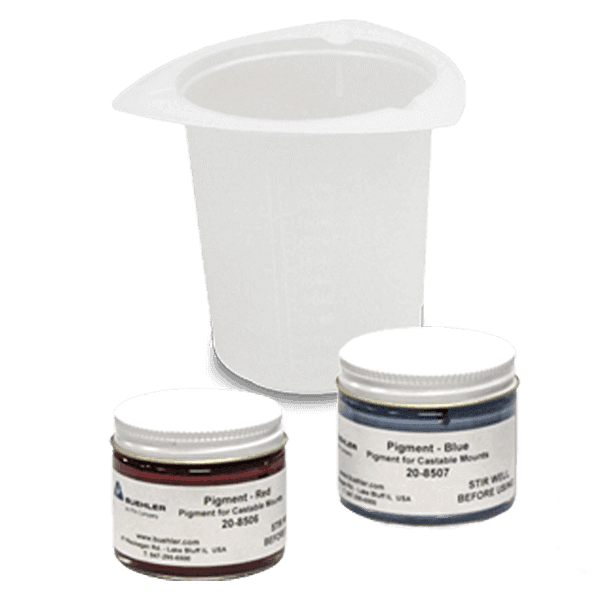

Consumables and Accessories