Buehler Sectioning & Cutting

Automatic Abrasive Sectioning Machines

Automatic abrasive cutters for small, medium, and oversized samples, so every part enters preparation with a clean, consistent section.

AbrasiMatic 300

The Buehler AbrasiMatic 300 is a 12-inch automatic and manual abrasive cutter designed for high-throughput metallographic preparation.

AbrasiMet® L Pro

The Buehler AbrasiMet L Pro is a high-performance automatic cutter for medium to high-volume QC workflows.

AbrasiMet® XL Pro

The Buehler AbrasiMet XL Pro floor-standing cutter handles large and oversized samples with 14–18" blades.

Manual Abrasive Sectioning Machine

Robust machines to make fast and efficient cuts so you can move through to the next stage quickly, ideal for non-delicate samples.

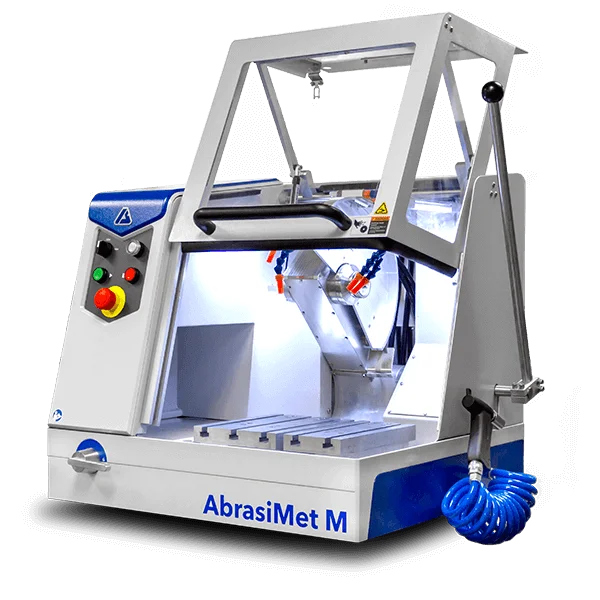

AbrasiMet® M

The Buehler AbrasiMet M is a 10" / 12" benchtop manual abrasive cutter designed as a robust solution for quick cuts on small to medium samples. High chamber visibility, an ergonomic cutting arm, and a powerful 5.5 HP (4 kW) motor help deliver consistent, repeatable sections in busy labs.

Optimized for manual abrasive sectioning, the AbrasiMet M combines efficient coolant management, easy access to the cutting area, and tool-less blade changes to keep operators productive throughout the day.

Manual Precision Sectioning Machines

Gravity‑fed machines deliver a high‑quality cut surface at lower feed rates. These reliable systems are ideal for small and delicate samples such as electronics and specialty materials.

IsoMet® 1000

The IsoMet 1000 Precision Cutter is a 7" gravity‑fed tabletop saw that balances cut consistency and versatility for metals, ceramics, and electronic components while minimizing deformation.

IsoMet® Low Speed

The IsoMet Low Speed Precision Cutter is a 5" gravity‑fed saw engineered for the gentlest cuts on delicate samples, using low‑speed control and a precision micrometer for accurate sectioning.

PetroThin Precision Sectioning Machine

The PetroThin Thin Section Machine combines an 8" diamond blade with a cup grinding wheel to re‑section and thin petrographic, concrete, and biological samples down to consistent ultra‑thin sections.

Buehler Mounting Machine

Hot mounting Machines

Engineered for high-speed, high-quality mounting, our hot mounting machines deliver superior edge retention and uniform sample preparation using heat and pressure technology.

SimpliMet® 4000 Hot Mounting Machine

The SimpliMet® 4000 is a fully automatic hot mounting press designed for production-level sample preparation. It features 7 mount size options, delivers consistent results, and enables 2 samples per cycle for efficient workflow optimization.

Cold Mounting Machines

Perfect for heat-sensitive materials, our cold mounting systems use vacuum technology to eliminate voids and air bubbles, ensuring pristine epoxy mounts without thermal damage.

SimpliVac® Vacuum Mounting System

The SimpliVac® is an advanced vacuum mounting system that removes trapped air and eliminates void formation in epoxy mounts. With an intuitive touchscreen interface, users can precisely control vacuum pressure, cycle time, and cycles for optimal mount quality.

Buehler Grinding and Polishing Machine

EcoMet® 30

Compact and intuitive system engineered for low to medium volume applications. The EcoMet 30 features a programmable touchscreen interface, available in single or dual platen configurations, and integrates up to 3 Burst dispensing modules to automate individual polishing steps while optimizing sample preparation efficiency.

AutoMet® 250

Versatile platform designed for medium to high-volume production environments. The AutoMet 250 features reliable automatic operation with membrane control panel, accommodates samples up to 1.5" diameter, and supports up to 5 Burst modules for comprehensive automation of grinding and polishing sequences.

AutoMet® 250 Pro

Enhanced version combining proven reliability with advanced features for professional laboratories. The AutoMet 250 Pro integrates programmable sequences, superior control systems, and modular expansion capabilities. Perfect for demanding applications requiring precision and repeatability across high-volume sample processing.

AutoMet® 300 Pro

Advanced system engineered for demanding high-volume operations with superior precision. The AutoMet 300 Pro delivers enhanced performance capabilities, touchscreen interface with programmable sequences, accommodates larger samples, and integrates multiple Burst modules for maximum workflow automation and consistent quality outcomes.