Leica DM6 M LIBS Light Microscope

The DM6 M LIBS module turns a DM6 M (or DM6000 M) microscope into a 2‑in‑1 solution that performs both high‑quality optical inspection and rapid, location‑specific chemical analysis via Laser Induced Breakdown Spectroscopy (LIBS) in about one second per spot. It is aimed at materials and cleanliness analysis workflows where users need to see microstructure and elemental composition together—for example in metals, alloys, coatings, ceramics, minerals, and particulate contamination—while avoiding separate SEM/EDS preparation, sample transfer, and long measurement times.

No SEM sample preparation required

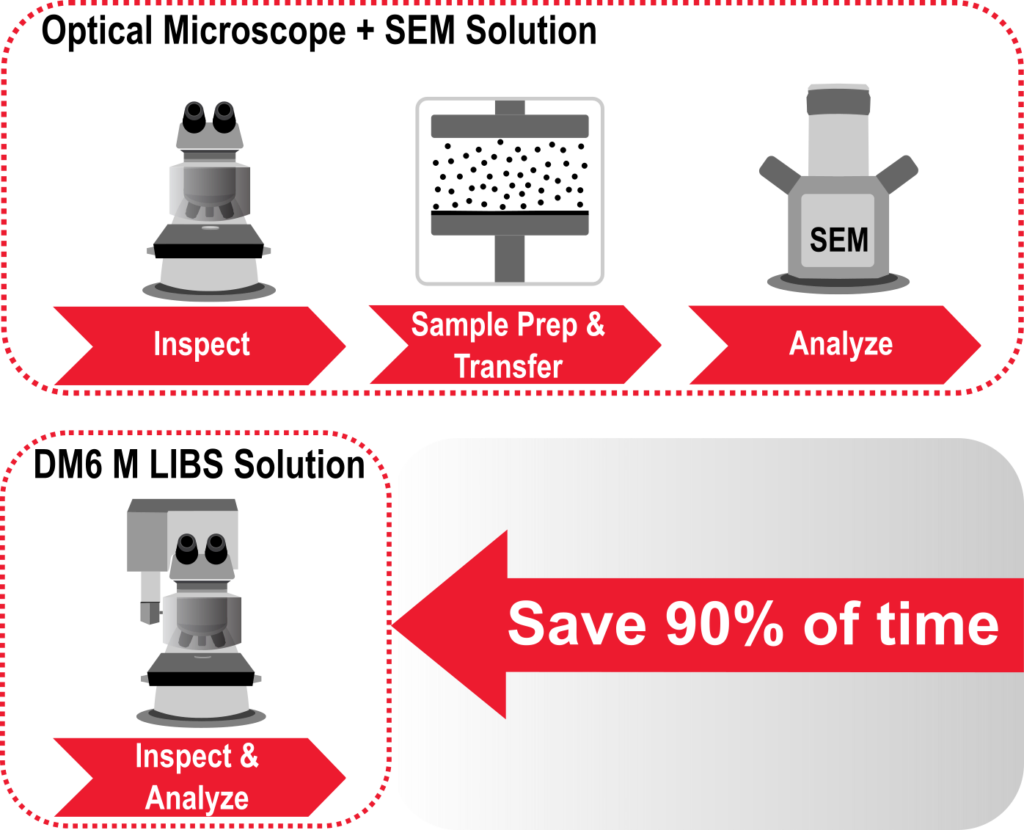

Why does materials analysis with the DM6 M LIBS solution take 90% less time? Because it requires:

- no sample preparation nor transfer;

- no system adjustment; and

- no relocating the region of interest (ROI).

Reduce the workflow

Reduce the workflow to just one step and focus on results.

Technical Specification of Leica DM6 M LIBS Light Microscope

Industries We Serve

DM6 M LIBS supports metallography, contamination control, and materials analysis across a wide range of industrial markets.

Key Features and Benefits of Leica DM6 M LIBS Light Microscope

The system performs optical inspection and qualitative chemical analysis in a single step, saving up to 90 % of the time compared with conventional SEM/EDS workflows.

- Obtain a chemical fingerprint of the area in the image in about one second per LIBS shot.

- Reduce or eliminate SEM scheduling, vacuum time, and sample transfers for many routine questions.

Samples are analyzed in air without coating, vacuum, or special stubs, so you can work directly on many as‑received or polished parts.

- No transfer between instruments and no need to relocate the region of interest.

- Shorter turnaround and lower consumable and labor costs for routine composition checks.

Visual appearance and elemental information are available together, so users can quickly decide whether further high‑end analysis is needed.

- In many cases, LIBS data is sufficient to decide next steps without additional SEM/EDS.

- Supports tasks like identifying contamination sources, verifying alloy grades, or screening suspect parts.

DM6 M LIBS covers cleanliness analysis, microstructure evaluation, depth profiling, and layer analysis on metals, alloys, ceramics, minerals, and coatings.

- Combine with cleanliness software to correlate particle morphology and composition on filters.

- Use micro‑drilling for depth profiles, layer‑by‑layer composition, or surface cleaning of oxides and contamination.

Built on the DM6 M platform, the system offers a wide magnification range, multiple contrast methods, and motorized functions for reproducible imaging.

- Use brightfield, darkfield, polarization, and DIC to visualize fine structures in true color before LIBS analysis.

- Encoded illumination and focus functions help recall the same settings at any time and across users.

Existing DM6 M or DM6000 M microscopes can be upgraded with the LIBS module, so you can add chemical analysis without replacing your optical system.

- Protect previous microscope investments while adding new analytical capabilities.

- Scale from basic microstructure inspection to full 2‑in‑1 materials analysis as requirements grow.

Applications and Usecases of Leica DM6 M LIBS Light Microscope

Inspect filter membranes or component surfaces and identify both the morphology and chemical composition of contamination in a single workflow.

- Locate critical particles and determine if they are metallic, organic, or mineral in origin.

- Trace contamination sources quickly to support standards such as VDA 19.

Combine brightfield, DIC, and LIBS to analyze grains, phases, and inclusions in metals, alloys, ceramics, and minerals directly on polished sections.

- Check whether phases meet specified alloy compositions at defined locations.

- Characterize non‑metallic inclusions in steel or other materials without switching to SEM/EDS for every feature.

Use LIBS micro‑drilling to analyze the composition of each layer in multi‑coated or painted materials and to see how elements change with depth.

- Verify coating build‑up on metals, such as primers, paints, or functional layers.

- Check for diffusion of alloying elements or contaminants into the bulk material.

Exploit the ablation effect of LIBS to remove thin oxide layers or surface contamination while monitoring the underlying material.

- Clean small regions prior to further micro‑analysis or joining processes.

- Confirm that cleaning has reached the desired base material without over‑removal.

Investigate cracks, inclusions, and foreign phases on failed parts or test coupons visually and chemically at the same time.

- Screen large areas optically, then trigger LIBS only at critical locations to speed up investigations.

- Decide rapidly whether more detailed high‑end analysis is required for root cause confirmation.

Use the 2‑in‑1 system to teach the link between microstructure and composition, or to build application‑specific spectral libraries.

- Demonstrate how changes in process parameters affect both structure and chemistry of materials.

- Create and refine LIBS reference datasets tailored to your own alloys, coatings, or contaminants.

Frequently Asked Questions

Answers to common questions about the DM6 M LIBS 2‑in‑1 materials analysis solution.

DM6 M LIBS is a materials microscope that combines high‑quality optical imaging with integrated Laser Induced Breakdown Spectroscopy, so you get both visual and chemical information from the same instrument.

A LIBS measurement typically takes around one second per spot, providing a qualitative chemical fingerprint of the microstructure region you see in the microscope image.

Many routine questions can be answered directly with DM6 M LIBS, reducing the need for SEM/EDS. For complex cases, LIBS quickly indicates where detailed SEM analysis will be most useful.

Samples are analyzed in air without vacuum or coating. Polished sections are ideal for quantitative comparison, but many as‑received parts and filter membranes can be examined directly.

DM6 M LIBS is suited for metals and alloys, ceramics, minerals, glasses, coatings, and particles collected on filters, as long as they can withstand local laser ablation at the measurement spot.

Each LIBS shot produces a tiny ablation crater, typically only a few micrometers in diameter and depth. For most investigations this has no impact on the usability of the part, but it should be considered for critical surfaces.

Yes. The software lets you store spectra and link them to known materials so you can create application‑specific reference libraries for your alloys, coatings, or contaminants.

Typical uses include cleanliness analysis of components, microstructure and inclusion characterization, depth profiling of coated parts, layer analysis of paints, and general failure analysis in QA and R&D labs.

Many DM6 M and DM6000 M microscopes can be retrofitted with the LIBS module, turning them into a 2‑in‑1 visual and chemical analysis system without replacing the entire instrument.

Operation is designed to be straightforward: focus on the area of interest, click to trigger LIBS, and interpret the automatically processed spectrum. Routine users can work with predefined methods, while experts can fine‑tune parameters if needed.