Buehler AbrasiMatic 300 – Abrasive Cutter

Buehler AbrasiMatic 300 | Automatic and Manual Abrasive Cutter

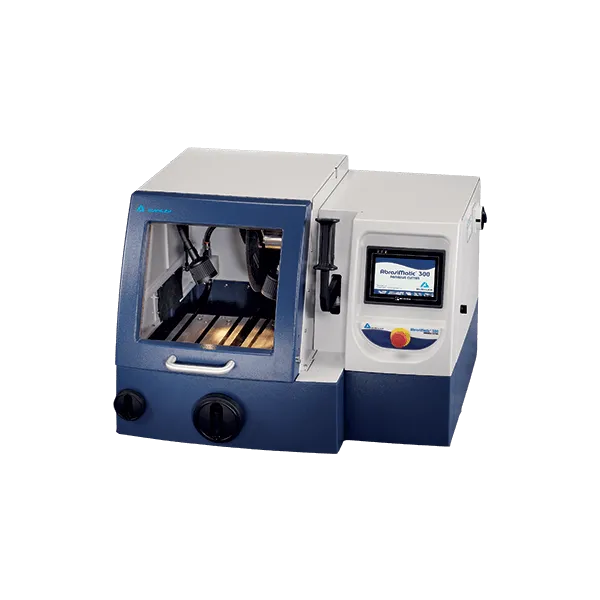

The Buehler AbrasiMatic 300 is a 12-inch (305 mm) automatic and manual abrasive cutter designed for high-throughput metallographic sample preparation. Built for durability in harsh environments, this benchtop abrasive cutter bridges the gap between manual “chop” saws and fully automated production machines.

Equipped with a powerful 5.5 HP (4 kW) motor, the AbrasiMatic 300 easily powers through hardened steel, titanium, and superalloys. Its defining feature, SmartCut™ Technology, automatically adjusts feed rates to prevent motor stalls and eliminate thermal damage, ensuring burn-free cutting and pristine sample quality for failure analysis and quality control.

Whether you are performing automotive parts sectioning on camshafts or require precise fastener testing equipment, the AbrasiMatic 300 delivers the versatility of 3-axis movement (X, Y, Z) in a compact, lab-friendly footprint.

Technical Specification of Buehler AbrasiMatic 300 Abrasive Cutter

| Motor Power | 5 HP [3.7 kW] |

| Power Consumption | 4.0 kW |

| Wheel Diameter | Max 12 in [305 mm] |

| Arbor Size | 1.25 in [32 mm] |

| Wheel Speed | 2600 rpm @ 50/60 Hz (8200 surface ft/min) |

| Max Cut Diameter | 4.375 in [110 mm] |

| Cutting Torque | 121 in/lb [14 Nm] |

| Auto Feed Rate | 0.7 - 5 in/min [0.3 - 2 mm/sec] |

| Sound Rating | 78 dBA (no load) |

| Compliance | CE Marked |

| Travel (X / Y / Z) |

X: 2.75 in [70 mm] Y: 10.25 in [260 mm] Z: 5.75 in [150 mm] |

| Cutting Chamber | 36 W x 22 D x 8 H in |

| Window Size | 14 W x 12 H in [355 x 300 mm] |

| T-Slot Table | 14.375 W x 10 D in (12mm wide T-slots) |

| Control Panel | 7 in Touchscreen [IP 65] |

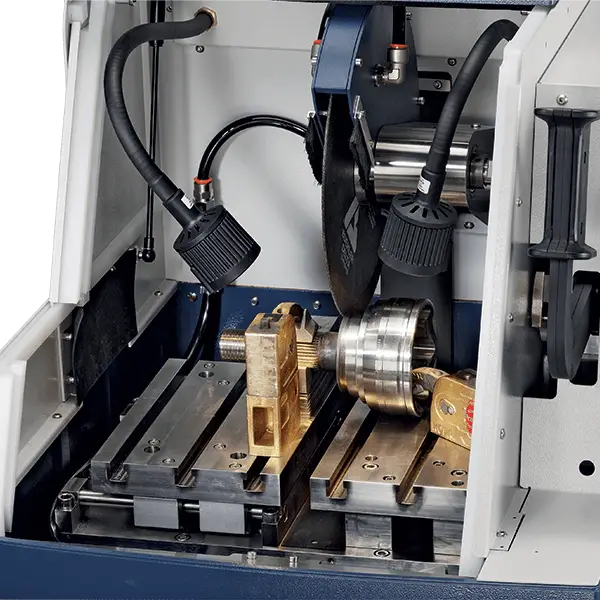

| Lighting | Two LED Goosenecks |

| Coolant Tank | 22 gal [83 L] |

| Voltage Options | 200-240V / 380-460V (3-Phase) |

| Max Current |

15.7A @ 220V 9.1A @ 380V / 7.9A @ 460V |

| Fume Extractor | 3 in [75 mm] cut-out |

Key Features & Benefits of Buehler AbrasiMatic 300 Abrasive Cutter

- ✓ Dual-Mode Operation: Combines automatic Y-axis feed with manual Z-axis chop for ultimate flexibility.

- ✓ 12-inch Capacity: Accommodates standard 305mm abrasive wheels with a 1.25" (32mm) arbor.

- ✓ High-Torque Drive: Powered by a robust 5 HP (3.7 kW) motor designed for continuous production use.

- ✓ SmartCut™ Control: Intelligent load monitoring system automatically adjusts feed rate to prevent stalls.

- ✓ 3-Axis Travel: Features Z (150mm), Y (260mm), and optional X (70mm) travel for precise positioning.

- ✓ NEMA4 Touchscreen: Water-resistant IP65 control panel for safe operation in wet environments.

- ★ Maximized Throughput: Run programmed automatic cuts for batches, or quick manual cuts for single samples.

- ★ Burn-Free Results: SmartCut™ prevents thermal damage, preserving the true microstructure for analysis.

- ★ Reduced Downtime: The 5 HP motor powers through tough superalloys without stalling, reducing rework.

- ★ Consistent Quality: Automatic feed rates ensure every cut is identical, regardless of operator skill level.

- ★ Longer Wheel Life: Controlled cutting parameters significantly extend the life of abrasive consumables.

- ★ Operator Safety: Fully enclosed chamber with safety interlocks and electronic braking system.

Ordering Information

| AbrasiMatic 300 | |

|---|---|

| Standard Models (Y and Z Axis) | |

| Part Number | Voltage |

| 10-2190-260 | 200-240VAC, 60Hz |

| 10-2190-460 | 440-480VAC, 60Hz |

| 10-2190-400 | 380-400VAC, 50Hz |

| Advanced Models (With X Axis) | |

| 10-2193-260 | 200-240VAC, 60Hz |

| 10-2193-460 | 440-480VAC, 60Hz |

| 10-2193-400 | 380-400VAC, 50Hz |

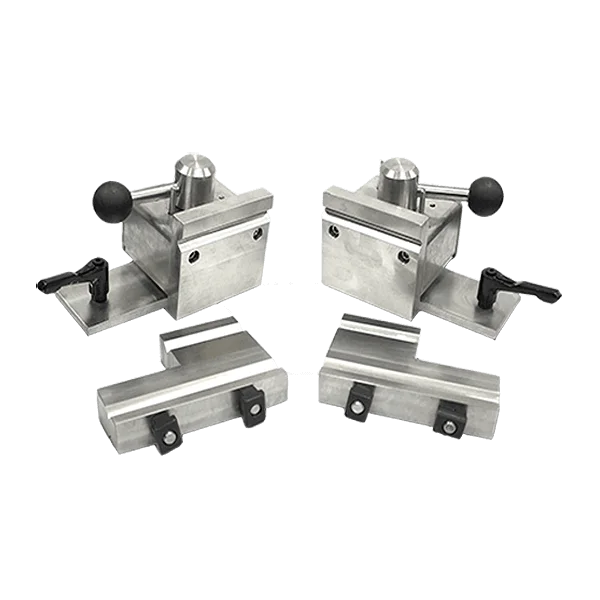

Consumables and Accessories

Proven Reliability of Buehler AbrasiMatic 300 Abrasive Cutter

Powerful & Reliable Motor

The AbrasiMatic 300 features a powerful 5Hp [3.7kW] motor. Accepting blades up to 12”[305mm] diameter, the motor can power through parts as large as 4.375mm [110mm] tall. To greatly improve reliability and lifetime, the motor is removed from the cutting chamber so it is protected from debris and coolant.

Large Chamber & Retractable Hood

The chamber stretches the entire depth of the machine to allow for long cuts in the Y direction giving the user more cut flexibility. The chamber features LED lights to illuminate the cutting table to increase visibility. The hood opens up and folds backwards to further open up the chamber and allow for easy access during vising.

Easy to use 3-Axis Control

With over a decade of experience, we’ve est ablis ourselves as one of the pioneering agencies in the region decade.

Manual Operation

The machine features a manual Z handle to increase the number of cut modes available to the user. The manual cutting lever gives the user tactile feedback as they progress through the cut, just like on a manual machine

Recommended Sectioning Machines

Explore complementary Buehler sectioning solutions

Buehler AbrasiMet L Pro

Floor-standing abrasive cutter designed for larger samples and higher throughput sectioning tasks.

View Product

Buehler AbrasiMet XL Pro

Large-capacity abrasive cutter offering robust vising and advanced control for demanding sectioning jobs.

View Product

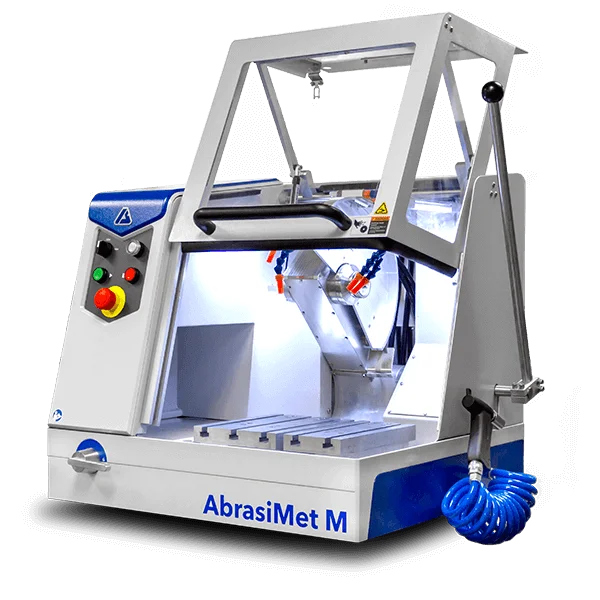

Buehler AbrasiMet M

Manual abrasive cutter suitable for versatile lab sectioning with straightforward, reliable operation.

View Product

Buehler IsoMet 1000

Precision saw for low-deformation cutting of delicate materials and small components.

View Product

Buehler IsoMet Low Speed Saw

Low-speed precision cutter optimized for fragile samples where minimal damage is essential.

View Product

Buehler Petrothin

Dedicated thin-sectioning system for petrographic and geological samples requiring precise thickness control.

View Product