Buehler IsoMet Low Speed Precision Cutter

Buehler IsoMet Low Speed | Gravity-fed Precision Sectioning Machine

The IsoMet Low Speed Precision Cutter is a compact, gravity-fed precision saw specifically engineered for sectioning the most delicate materials with minimal deformation. With a variable speed range of 0-300 RPM and a gentle weighted feed system, it is the industry standard for preparing samples that cannot withstand the heat or stress of high-speed cutting, such as soft metals, single crystals, and biological tissues.

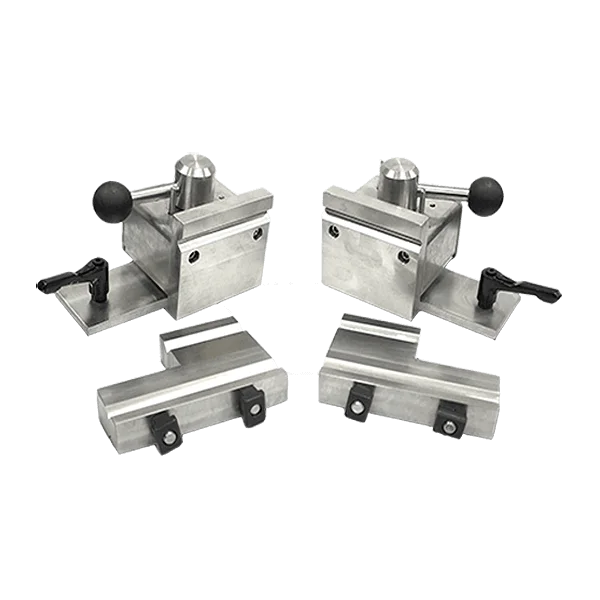

This tabletop precision cutter accommodates diamond wafering blades up to 5 inches [127mm] and features a built-in micrometer sample positioning system for precise cross-feed adjustments. Its versatile design supports a wide range of sample chucks and vises, allowing users to securely hold irregular shapes. Ideally suited for research laboratories, the IsoMet Low Speed ensures low kerf loss and superior surface quality for high-precision microstructural analysis.

Technical Specification of Buehler AbrasiMatic 300

| Operation Mode | Gravity Fed (Weighted Arm) |

| Blade Speed | 0 - 300 rpm (Variable) |

| Motor Power | 1/50 HP [15 W] DC |

| Max Blade Diameter | 5 in [127 mm] |

| Arbor Size | 0.5 in [12.7 mm] |

| Cut Capacity (Max) | 1.5 in [38 mm] Diameter |

| Load Weights | 25g Increments (0 - 600g) |

| Sample Positioning | Micrometer X-Axis |

| Machine Dims (WxDxH) |

10.5 x 12 x 25.5 in [267 x 305 x 648 mm] |

| Weight | 25 lbs [11.3 kg] |

| Controls | Analog Speed Dial |

| Coolant Tank | Built-in Reservoir (0.25 L) |

| Voltage (115V) | 115VAC, 50/60Hz |

| Voltage (220V) | 220VAC, 50/60Hz |

| Phase | Single Phase |

| Compliance | CE Directives |

Key Features & Benefits of Buehler AbrasiMatic 300

- ✓ Gentle Gravity Feed: Uses adjustable weights to apply minimal force for delicate samples.

- ✓ Precise Speed Control: Variable speed (0-300 RPM) prevents overheating and damage.

- ✓ Micrometer Adjustment: Integrated micrometer allows for accurate sample thickness control.

- ✓ Compact Design: Small 10.5" x 12" footprint fits easily into any lab space or fume hood.

- ✓ Versatile Vising: Compatible with a wide range of chucks for holding irregular shapes.

- ✓ Auto Shut-Off: Automatically stops the blade rotation when the cut is complete.

- ★ Deformation-Free Cuts: Low speed and force preserve the true microstructure of soft materials.

- ★ Low Kerf Loss: Thin diamond blades minimize material waste, ideal for rare samples.

- ★ User Friendly: Simple plug-and-play operation requires minimal training to use effectively.

- ★ Cost Efficient: Durable design with low maintenance requirements and consumable usage.

- ★ Quiet Operation: The DC motor runs silently, maintaining a comfortable lab environment.

- ★ Flexible Applications: Perfect for biomaterials, electronics, plastics, and minerals.

Ordering Information

| IsoMet Low Speed Precision Cutter | |

|---|---|

| Standard Models | |

| Part Number | Voltage |

| 11-1280-160 | 115VAC, 50/60Hz (Inches) |

| 11-1280-170 | 115VAC, 50/60Hz (Millimeters) |

| 11-1280-250 | 230VAC, 50/60Hz (Millimeters) |

Consumables and Accessories