Buehler IsoMet 1000 Precision Cutter

Buehler IsoMet 1000 | Gravity-fed Precision Sectioning Machine

The Buehler IsoMet 1000 is a versatile gravity-fed precision cutter designed for today’s most demanding laboratory environments. Featuring a broad speed range of 100-975 RPM, it allows operators to section a wide variety of delicate materials—from brittle crystals and electronics to composites and biomaterials—with virtually no deformation. Its fully enclosed tabletop design ensures safety while providing a clean, quiet workspace for precision sample preparation.

This tabletop precision cutter accepts diamond wafering blades up to 7 inches [178mm] in diameter, offering a maximum cut capacity of 2 inches [50mm]. The integrated micrometer sample positioning system allows for precise X-axis alignment, making it perfect for serial sectioning. With optional accessories like the rotating chuck for reduced cut time and the table saw attachment for larger PCBs, the IsoMet 1000 delivers flexibility unmatched by other gravity-fed saws.

Technical Specification of Buehler IsoMet 1000

| Operation Mode | Gravity Fed (Weighted Arm) |

| Blade Speed | 100 - 975 rpm (Adjustable) |

| Motor Power | 1/8 HP [90 W] |

| Max Blade Diameter | 7 in [178 mm] |

| Arbor Size | 0.5 in [12.7 mm] |

| Cut Capacity (Max) | 2.0 in [50 mm] Diameter |

| Load Range | 0 - 500g (up to 800g w/ Acc) |

| Sample Positioning | Micrometer X-Axis Control |

| Machine Dims (WxDxH) |

15.5 x 20.25 x 12 in [394 x 514 x 305 mm] |

| Weight | 56 lbs [25 kg] |

| Controls | Membrane Touch Panel (LED) |

| Blade Dressing | Manual Dressing Stick Vise |

| Coolant Tank | Removable Tray (1 pint / 0.5L) |

| Voltage | 85-264VAC, 50/60Hz (Universal) |

| Phase | Single Phase |

| Compliance | CE Directives |

Key Features & Benefits of Buehler IsoMet 1000

- ✓ Gravity Fed System: Uses sliding weights (0-500g) to apply constant, gentle cutting force.

- ✓ Wide Speed Range: Adjustable blade speed from 100 to 975 RPM for various material hardness.

- ✓ Micrometer Positioning: Built-in inch/metric micrometer for precise X-axis sample alignment.

- ✓ Rotating Chuck Support: Optional accessory rotates the sample to reduce heat and cut time.

- ✓ Table Saw Attachment: Converts the unit into a manual trim saw for cutting larger PCBs.

- ✓ SmartStop Function: Automatically stops the motor when the cutting arm completes the section.

- ★ Minimal Deformation: Low-speed gravity cutting preserves the microstructure of delicate samples.

- ★ Versatile Applications: Ideal for everything from soft biomaterials to hard ceramics and fasteners.

- ★ Easy Clean-up: The removable coolant tray makes fluid changes and debris removal fast and simple.

- ★ Consistent Results: Weighted feed removes operator variability, ensuring reproducible cuts.

- ★ Compact Footprint: Fits easily on any lab benchtop without requiring external plumbing.

- ★ Cost Effective: Uses standard 7" wafering blades and requires minimal maintenance.

Ordering Information

| IsoMet 1000 Precision Cutter | |

|---|---|

| Gravity Fed Precision Saw | |

| Part Number | Voltage |

| 11-2180 | 85-264VAC, 50/60Hz (Universal) |

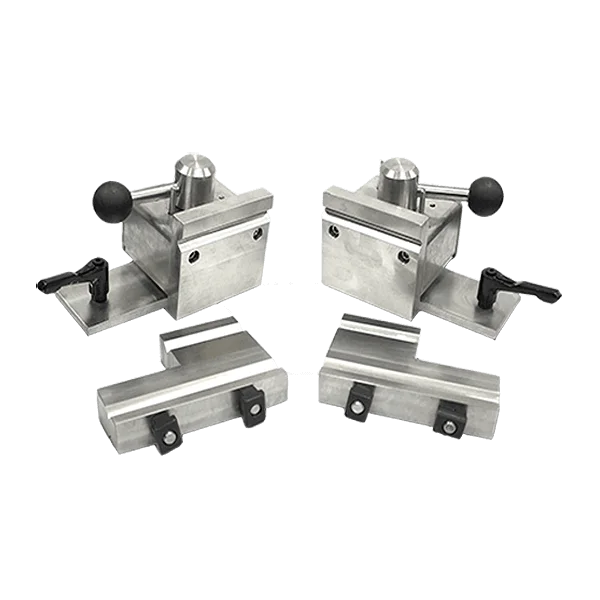

Consumables and Accessories