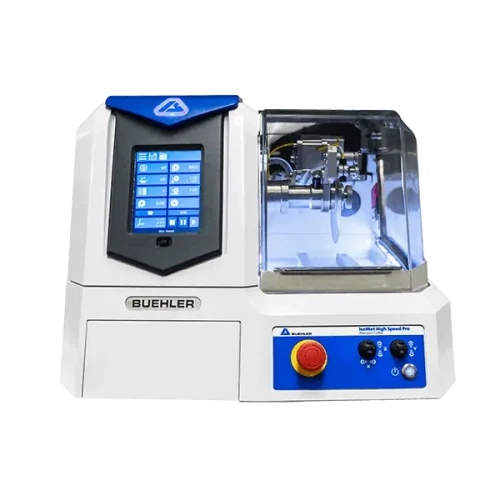

Buehler IsoMet High Speed Pro

Buehler IsoMet High Speed Pro Precision - Automatic Precision Sectioning Machine

The IsoMet High Speed Pro is Buehler’s most advanced benchtop precision cutter, engineered for laboratories that demand both speed and extreme accuracy. Powered by a market-leading 2.68 HP [2kW] motor, it drives diamond wafering blades up to 5000 RPM, delivering rapid, deformation-free cuts on microelectronic components, bone, biomaterials, and thermal spray coatings. Its robust design minimizes vibration, ensuring 2 micron precision alignment for the most delicate sectioning tasks.

This automatic precision sectioning machine features a 3-axis (X, Y, Z) blade movement system and the intuitive SmartCut™ load control, which automatically adjusts feed rates to prevent sample damage. The integrated Rapid Rail vise system and laser alignment tool allow operators to set up complex cuts in seconds. With an automatic dressing system that keeps blades sharp during operation, the IsoMet High Speed Pro guarantees consistent, high-quality results for high-volume metallography.

Technical Specification of Buehler IsoMet High Speed Pro

| Motor Power | 2.68 HP [2 kW] |

| Blade Speed | 1000 - 5000 rpm |

| Cut Capacity (Diameter) | 2.8 in [71 mm] |

| Feed Rate Range | 0.04 - 1 in/min [1.2 - 25.4 mm/min] |

| Operation Modes | Automatic, Manual, SmartCut™ |

| Blade Movement | 3-Axis (X, Y, Z) Control |

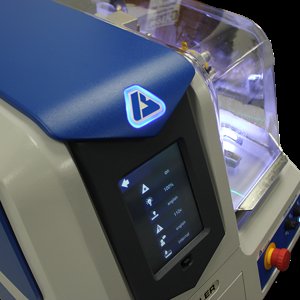

| Controls | Touchscreen + Joystick |

| Blade Size | 3 - 8 in [76 - 203 mm] |

| Noise Level | 58 dB (Ultra Quiet) |

| Machine Dims (WxDxH) |

24 x 30 x 19 in (Closed) [610 x 762 x 483 mm] |

| Weight | 157 lbs [71.2 kg] |

| Cut Chamber Size | 9 x 20 in [228 x 508 mm] |

| Cut Length Range | 0.01 - 7.25 in [1 - 184 mm] |

| Coolant System | Built-in Recirculating (1 gal / 4L) |

| Main Power | 100 - 240VAC, 50-60Hz (1-Phase) |

| Safety Features | Interlock Hood, E-Stop |

| Compliance | CE Directives |

Key Features & Benefits of Buehler IsoMet High Speed Pro

- ✓ 2kW High-Speed Motor: Strongest in class (2.68HP) motor drives blades up to 5000 RPM.

- ✓ SmartCut™ Load Control: Automatically monitors motor load and adjusts feed rate to prevent burns.

- ✓ 3-Axis Blade Control: Precise X, Y, and Z movement allows for rapid alignment and serial slicing.

- ✓ Automatic Dressing System: Mechanically dresses the blade during cutting to maintain sharpness.

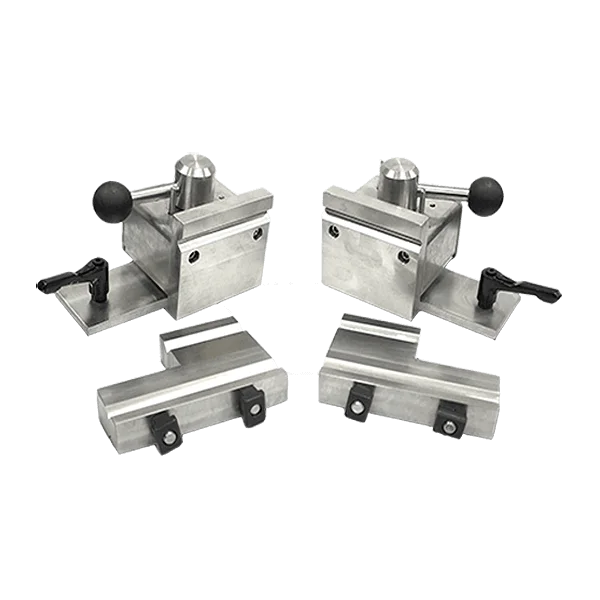

- ✓ Rapid Rail System: Quick-slide vise system lets you reposition samples in seconds.

- ✓ Laser Alignment: Integrated green laser projects the exact cut line for faster setup.

- ★ Faster Throughput: Cut 2.5X faster than competitors without sacrificing surface quality.

- ★ Consistent Quality: Automatic dressing ensures every cut is as clean as the first.

- ★ Hands-Off Serial Sectioning: Program multiple cuts on one sample with automatic X-axis indexing.

- ★ Sample Protection: SmartCut™ prevents force overload, saving delicate composites and electronics.

- ★ Clean & Safe: Fully enclosed, ultra-quiet (58dB) operation with built-in fluid recirculation.

- ★ Intuitive Operation: 6.5" touchscreen stores custom methods for repeatable results.

Ordering Information

| IsoMet High Speed Pro | |

|---|---|

| Automatic Precision Cutter | |

| Part Number | Voltage |

| 11-2800 | 100 - 240VAC, 50-60Hz (1-Phase) |

Consumables and Accessories