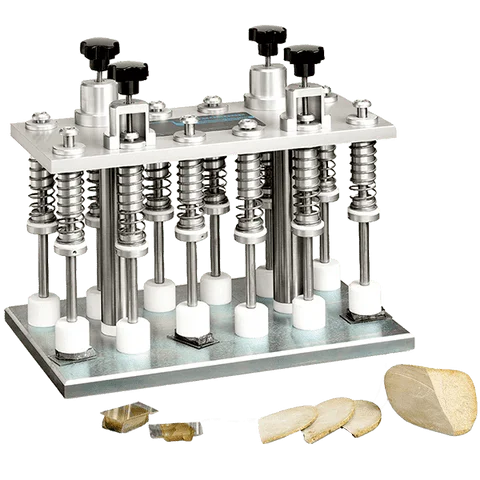

Buehler PetroThin Thin Sectioning Machine

Buehler PetroThin Sectioning Machine | Rock & Mineral Thin Section Machine

The PetroThin Thin Sectioning Machine is a specialized, high-precision instrument designed for the rapid preparation of 30-micron thin sections from a variety of materials, including rocks, minerals, concrete, ceramics, and bone. Its unique single-spindle design houses both a diamond cut-off blade and a diamond cup grinding wheel, allowing operators to re-section and grind samples to final thickness without removing the glass slide. This ensures perfect parallelism and eliminates the errors common with multi-step transfers.

Equipped with a universal vacuum glass slide chuck and a built-in vacuum pump, the PetroThin securely holds standard petrographic slides (such as 27x46mm) during the entire process. Two precision micrometers control the cutting and grinding positions to an accuracy of ±5µm, making it the industry standard for geological and petrographic sample preparation. The fully enclosed, corrosion-resistant housing features a recirculating coolant system to prevent heat damage to delicate specimens.

Technical Specification of Buehler PetroThin Sectioning Machine

| Configuration | Single Spindle (Cut & Grind) |

| Motor Power | 1/3 HP [250 W] |

| Wheel Speed (60Hz) | 2200 rpm |

| Wheel Speed (50Hz) | 2100 rpm |

| Cut-Off Blade | 8 in [203 mm] Continuous Rim |

| Grinding Cup | 8 in [203 mm] Diamond Cup |

| Thickness Precision | ± 5 µm (Micrometer Controlled) |

| Slide Holding | Vacuum Chuck (Built-in Pump) |

| Machine Dims (WxDxH) |

23.5 x 19 x 16 in [597 x 483 x 406 mm] |

| Weight | 96 lbs [44 kg] |

| Vacuum Capacity | 20 in Hg (approx) |

| Filter System | In-line Vacuum Filter w/ Auto-Drain |

| Coolant System | Recirculating (Water/Glycol/Oil) |

| Micrometer 1 | Cutting Position Control |

| Micrometer 2 | Grinding Thickness Control |

| Compliance | CE Directives |

Key Features & Benefits of Buehler PetroThin Sectioning Machine

- ✓ Single Spindle Design: Both the cutting blade and grinding cup are mounted on one shaft for perfect alignment.

- ✓ Vacuum Slide Chuck: Universal chuck uses vacuum pressure to firmly hold slides without adhesives.

- ✓ Micrometer Control: Two precision micrometers allow for ±5µm accuracy in cutting and grinding steps.

- ✓ In-Line Vacuum Filter: Protects the pump from moisture and debris, with an auto-drain feature.

- ✓ Corrosion Resistant: Built with stainless steel and molded polymer components for long life.

- ✓ Dual Action Arm: Sample arm swings smoothly between the cut-off blade and the grinding cup.

- ★ Superior Parallelism: Eliminates re-mounting errors, ensuring the entire thin section is even.

- ★ High Throughput: Prepare a finished thin section in minutes compared to hours with manual lapping.

- ★ Standardized Results: Achieve consistent 30-micron thickness regardless of operator skill level.

- ★ Versatile Usage: Handles standard 27x46mm slides as well as 1x2", 1x3", and 2x3" formats.

- ★ Clean Operation: Enclosed splash guard and vacuum system keep the lab clean and safe.

- ★ All-in-One Solution: Combines resectioning and thinning in a single compact benchtop unit.

Ordering Information

| PetroThin Thin Sectioning System | |

|---|---|

| System Configuration | |

| Part Number | Voltage |

| 38-1450-160 | 115VAC, 60Hz (Includes Diamond Blade & Cup Wheel) |

| 38-1450-250 | 220VAC, 50Hz (Includes Diamond Blade & Cup Wheel) |

Consumables and Accessories