Buehler SimpliVac Vacuum Mounting System

Buehler SimpliVac | Advanced Vacuum System

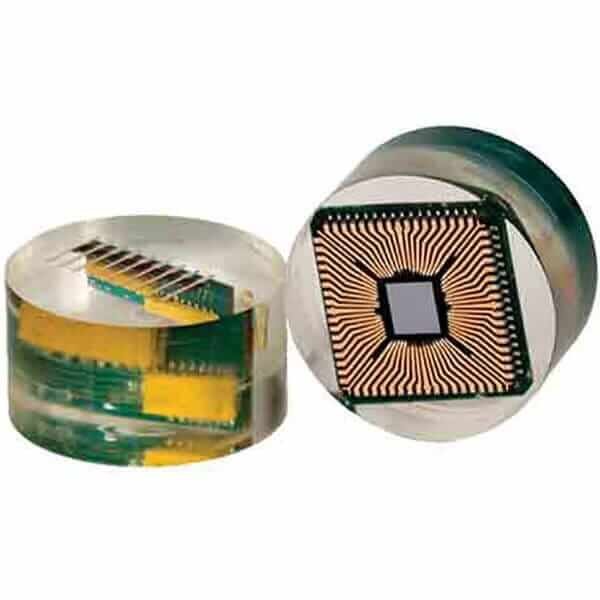

The SimpliVac™ vacuum mounting system is Buehler’s advanced digital vacuum impregnation solution for epoxy castable mounting, engineered to remove trapped air and fully impregnate porous or delicate specimens such as coatings, AM parts, ceramics and electronic components. With programmable vacuum level, time under vacuum and multi‑cycle vacuum–atmosphere sequencing in a large 9.4 in vacuum chamber, SimpliVac produces bubble‑free, edge‑retentive mounts that outperform conventional manual vacuum chambers in both quality and throughput.

Powered by your lab’s compressed air rather than a separate pump, the bench‑top SimpliVac system runs fully automated impregnation methods from an intuitive touchscreen interface with method storage, password protection and the ability to dispense epoxy under vacuum using disposable tubes and a rotating tray. Optimized for Buehler epoxy systems like EpoThin™, EpoxiCure™ and EpoHeat™, the SimpliVac vacuum mounting system helps metallography and QA labs achieve consistent, high‑quality castable mounts with minimal operator intervention, improved repeatability and efficient clean‑up via removable liners and accessories.

Technical Specification of Buehler SimpliVac

| System Type | Digital programmable vacuum mounting system for epoxy castable mounting. |

| Max Vacuum | 27.1 inHg [-92 kPa]. |

| Min Vacuum | -1.47 inHg [-5 kPa]. |

| Vacuum Control | Adjustable vacuum level, time under vacuum and number of cycles via touchscreen. |

| Vacuum Cycles | Automatic cycling between atmosphere and vacuum to release trapped air in porous samples. |

| Cycle Programmability | Save and recall methods; password protection to lock settings for consistent processing. |

| Dispensing Under Vacuum | Use disposable dispensing tubes and rotating tray to pour epoxy while under vacuum. |

| Power Consumption | 25 W (max). |

| Voltage | 100–240 VAC, 50–60 Hz, single phase. |

| Air Input | ≥ 0.6 MPa compressed air supply (external compressor required). |

| Machine Size | 12.8 in H × 19.2 in D × 18.6 in W [325 × 488 × 472 mm]. |

| Chamber Diameter | 9.4 in [240 mm] bowl for high sample volume and oversized specimens. |

| Weight | 51 lb [23 kg]. |

| User Interface | Intuitive touchscreen with method storage and system lockout. |

| Cleaning & Liners | Removable tray, bowl and liners; inertial dampening to prevent spills. |

| Intended Use | Vacuum epoxy impregnation for castable mounting of porous and delicate samples. |

Key Features & Benefits of Buehler SimpliVac

- ✓ Advanced Vacuum Impregnation: Digital, programmable vacuum system designed to optimize epoxy castable mounting and pore impregnation of porous samples.

- ✓ Multi‑Cycle Vacuum Control: Automatically cycles between atmosphere and vacuum with adjustable vacuum level, time and number of cycles to improve epoxy penetration.

- ✓ Intuitive Touchscreen Interface: All major functions on one screen, method storage and password protection for consistent processing and simplified training.

- ✓ Integrated Vacuum System: Uses your compressed air source; no external vacuum pump required, reducing complexity and maintenance.

- ✓ Large 9.4 in Chamber: Spacious bowl diameter supports high sample volume and oversized specimens for efficient batch processing.

- ✓ Dispensing Under Vacuum: Disposable dispensing tubes and a rotating sample tray allow pouring epoxy under vacuum for superior impregnation.

- ✓ Easy Cleaning & Liners: Removable tray and bowl with replaceable liners plus inertial dampening to prevent spills and keep the system clean.

- ★ Superior Mount Quality: Deep, uniform epoxy penetration delivers bubble‑free mounts with excellent edge retention for fragile and porous materials.

- ★ Reduced Technician Time: Programmable multi‑cycle operation runs automatically without user intervention between steps, freeing technicians for other tasks.

- ★ Higher Throughput: Large chamber volume and automated cycles enable more specimens to be processed per run, supporting busy metallography labs.

- ★ Consistent Results: Saved methods and locked parameters ensure repeatable vacuum mounting conditions across operators and shifts.

- ★ Reliable, Compact Design: Robust construction, low power draw and integrated vacuum system deliver dependable performance in a space‑efficient footprint.

- ★ Optimized for Buehler Epoxy: Pairs perfectly with EpoThin, EpoxiCure, EpoHeat and other Buehler epoxy systems for complete castable mounting workflows.

Ordering Information

| SimpliVac™ Vacuum Mounting System | |

|---|---|

| Part Number | Voltage |

| 20-1500 | 100–240 VAC, 50–60 Hz, Single Phase |

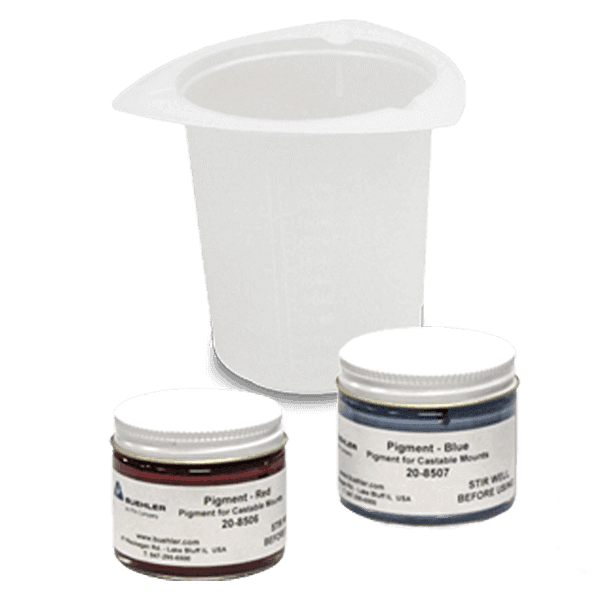

Consumables and Accessories