Abrasive Sectioning Machines

Automatic Abrasive Sectioning Machines

Automatic abrasive cutters for small, medium, and oversized samples, so every part enters preparation with a clean, consistent section.

AbrasiMatic 300

The Buehler AbrasiMatic 300 is a 12-inch automatic and manual abrasive cutter designed for high-throughput metallographic preparation.

AbrasiMet® L Pro

The Buehler AbrasiMet L Pro is a high-performance automatic cutter for medium to high-volume QC workflows.

AbrasiMet® XL Pro

The Buehler AbrasiMet XL Pro floor-standing cutter handles large and oversized samples with 14–18" blades.

Manual Abrasive Sectioning Machine

Robust machines to make fast and efficient cuts so you can move through to the next stage quickly, ideal for non-delicate samples.

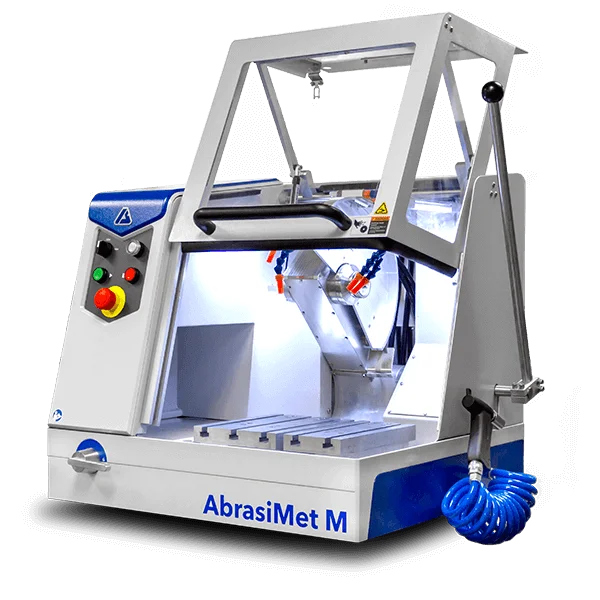

AbrasiMet® M

The Buehler AbrasiMet M is a 10" / 12" benchtop manual abrasive cutter designed as a robust solution for quick cuts on small to medium samples. High chamber visibility, an ergonomic cutting arm, and a powerful 5.5 HP (4 kW) motor help deliver consistent, repeatable sections in busy labs.

Optimized for manual abrasive sectioning, the AbrasiMet M combines efficient coolant management, easy access to the cutting area, and tool-less blade changes to keep operators productive throughout the day.

Manual Precision Sectioning Machines

Gravity‑fed machines deliver a high‑quality cut surface at lower feed rates. These reliable systems are ideal for small and delicate samples such as electronics and specialty materials.

IsoMet® 1000

The IsoMet 1000 Precision Cutter is a 7" gravity‑fed tabletop saw that balances cut consistency and versatility for metals, ceramics, and electronic components while minimizing deformation.

IsoMet® Low Speed

The IsoMet Low Speed Precision Cutter is a 5" gravity‑fed saw engineered for the gentlest cuts on delicate samples, using low‑speed control and a precision micrometer for accurate sectioning.

PetroThin Precision Sectioning Machine

The PetroThin Thin Section Machine combines an 8" diamond blade with a cup grinding wheel to re‑section and thin petrographic, concrete, and biological samples down to consistent ultra‑thin sections.

Sectioning and Cutting Consumables

Buehler’s premium abrasive and precision cutting blades and coolants to optimize cutting speed and cost in your sample preparation process.

Pair your cutters with premium abrasive blades, precision blades, and coolants to get fast sectioning, long consumable life, and high‑quality cut surfaces.

Blades for Abrasive Cutters

Performance‑proven resin and rubber‑bonded abrasive blades engineered for efficient cutting, extended lifetime, and minimal surface deformation on a wide range of metallic materials.

Blades for Precision Cutters

Thin diamond and CBN blades for delicate sectioning with superb surface quality on hard or sensitive materials, available for both low‑speed and high‑speed precision cutters.

Coolants for Sectioning & Cutting

Water‑miscible and oil‑based cutting coolants formulated to dissipate heat, remove swarf, and maintain good blade life and cut quality on abrasive and precision cutters.

Accessories for Sectioning Machines

Accessories for Abrasive Cutters

View our various abrasive vising options to find the ones that best align with your sample material and process needs.

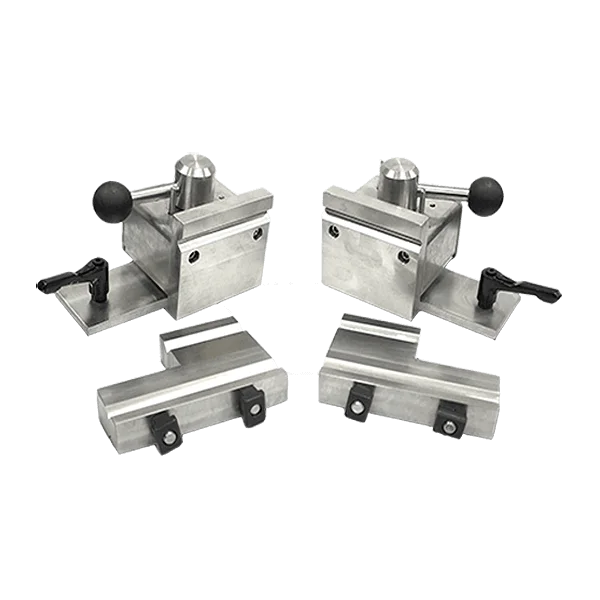

Abrasive Vising

Learn more about our full range of small, medium, and large vising options designed to securely clamp your samples and make setup fast and repeatable.

From simple workhorse vises to flexible sliding fixtures, these accessories help position parts consistently and support safer, higher‑quality abrasive cuts.

Abrasive Vising Page ➜Accessories for Precision Cutters

View our various precision clamping and flange options to find the ones that best align with your sample material and process needs.

Precision Vising

Compact precision vises designed to hold small samples securely in low‑speed and high‑speed precision cutters, improving positioning accuracy and repeatability.

Precision Flanges

Matched precision flanges that support thin diamond and CBN blades, helping to minimize runout and improve surface finish on precision‑cut samples.

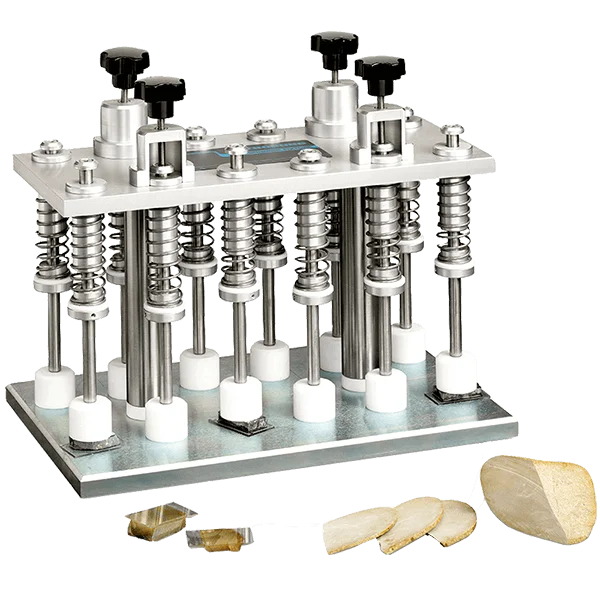

PetroBond Mounting Apparatus

The PetroBond mounting apparatus holds multiple petrographic specimens for simultaneous epoxy mounting, improving throughput and section consistency.